Softback, 297 mm x 210 mm (A4), 202 pages, profusely illustrated with drawings and photographs in colour.

Softback, 297 mm x 210 mm (A4), 202 pages, profusely illustrated with drawings and photographs in colour.

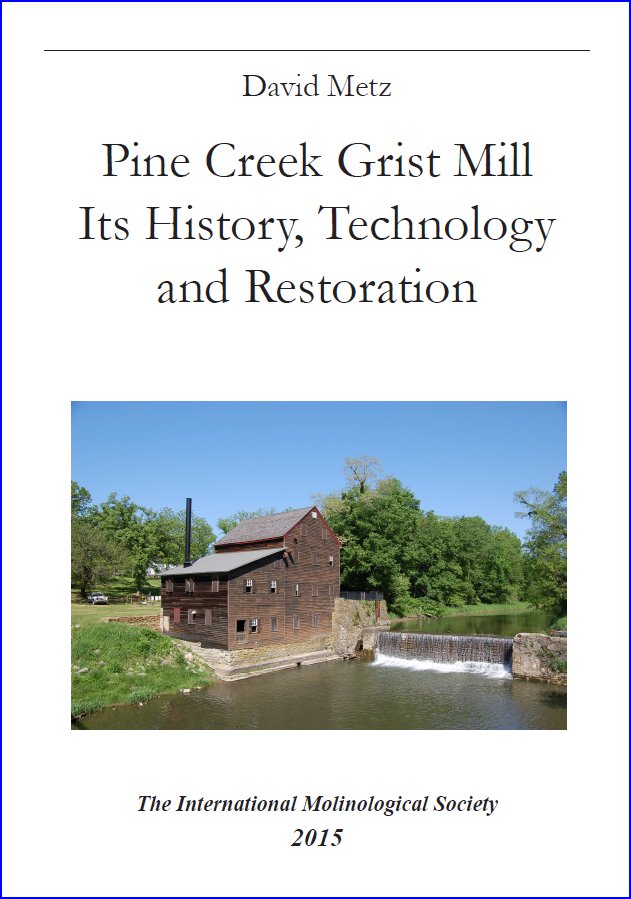

This latest book in the Bibliotheca Molinologica series concentrates on one mill located near Muscatine, a town on the west bank of the River Mississippi in the mid-western state of Iowa in the USA. When the Pine Creek Mill was first established in the 1830s by Benjamin Nye the River Mississippi was the frontier between the infant United States and Indian Territory. The mill’s history is traced using documents, eye witness accounts, and evidence from the mill building itself. This history runs from first using the American flat milling technique, as described and patented by Oliver Evans, which was powered by a waterwheel, through the various modifications and alterations that were necessary during the remainder of the 19th century for the mill to remain competitive. The lives of people involved with the mill during its operation are also highlighted, from Benjamin Nye’s family problems that led to his violent death, to the near fatal great flood of 1883, and the emigration to a new life in the USA of an East Prussian miller. Fortunately the mill stopped operating just as the land around the mill became the Wild Cat Den State Park which helped preserve the mill until its recent restoration and opening to the public in the last 20 years by the Friends of Pine Creek Grist Mill.

The mill buildings and both prime movers, the water turbine and steam engine, are described as are the three processes that were installed in 1890, namely three stands of double roller mills for the production of flour from wheat with their associated cleaners, scourers and separators as well as the middlings purifier and various types of bolters. Another roller mill with three rolls, used for the corn (maize) process with all its associated ancillary machines, as well as the use of a single three feet diameter pair of millstone for producing animal feed, are also explained.

Very often those involved in the practical aspects of restoration are not interested in writing about their experiences and so valuable information often has to be learnt again on any subsequent restoration project. However, the restoration of Pine Creek Mill has been recorded from the beginning by the restorers themselves. This information has been not been used to give a blow by blow account of the actual restoration of the mill, but to explain the problems that can be encountered during restoration and to describe in detail the solutions that have been proved to be successful (even to listing the contact information for the sources of materials and services that have been used).

The restoration section of the book starts with a statement of the aims of the project and an explanation of its philosophy which lies behind all the difficult decisions that have to be made on such a project. This is followed by an outline of the management of such a project and a description of all the other aspects and activities that are necessary for the successful outcome of any restoration project. Given the nature of Pine Creek Mill there are comprehensive details of the problems associated with belt drives, shafts, bearings, chutes and elevators, and practical advice about how to repair, set up and maintain these essential parts of a 19th century mill. One of the major projects undertaken by the Friends of Pine Creek Mill was the restoration of the steam engine. Their approach and the techniques involved are fully described as they are relevant to the restoration of any complex machinery not just steam engines.

At the end of the day any restored mill has to be operated easily and safely in order to attract the interest and support of the public. For various reasons this has meant the use of electric motors to drive parts of the plant in the mill. This subject is de-mystified with explanations of the factors to be considered and recommendations on viable solutions. Once a mill is operational the use of the millstones and their maintenance becomes crucial, their basic installation and dressing are described together with balance the runner stone (both statically and dynamically) and the various issues around producing usable flour examined

Often molinologists are criticised by historians and archaeologists for not developing suitable dating methods for mills and mill machinery. This criticism is addressed by outlining the development of criteria for the dating machinery in the mill. Although these criteria have been developed in the context of a 19th century mid-western American mill, their approach and methods can be used with benefit at mills around the world.

This book gives an in-depth look at the practical aspects of mill restoration, its problems and possible solutions in a way that will give confidence to any team contemplating undertaking such a project no matter how large or small.

Table of Contents

Introduction

Chapter 1: The History of Pine Creek Mill

Benjamin Nye, Pioneer Iowa Settler

Benjamin Nye’s First Mill

Benjamin Nye’s First Grist Mill

Nye’s New Mill of 1850 – American Flat Milling

Benjamin Nye’s Death

New Owners

Beesley & Huchendorf – New Process Milling

The Great Flood of 1883

Herman Huchendorf – Roller Milling

The Missel Family at Pine Mills

Wildcat Den State Park and a New Beginning

Chapter 2: A Description of Pine Creek Mill

The Mill Building

Water Power at the Mill

Steam Power at the Mill

The Millstone Plant of 1890

The Corn Milling Plant of 1890

The Wheat Milling Plant of 1890

Chapter 3: The Restoration Philosophy and Management at Pine Creek Mill

Organization and Support

Funding

Safety

Practical Support - Tools & Supplies

Communications & Promotion

Websites & Social Networking,

Newspapers,

Radio & TV

Documentation of the Site & Record Keeping

Chapter 4: Auxiliary Electrical Power for Pine Creek Mill

Chapter 5: Basic Bearing Technology and Restoration

Wooden Bearings

Babbitt Alloy Bearings

Split Brass Bearings

Thrust Bearings

Turbine Bearings

Modern Self-aligning Ball Bearings

Line Shaft Alignment

Lubrication

Automatic Oilers

Chapter 6: Flat Belt Power Transmission

Flat Belts and Pulleys

Belt Tracking

The Belt with only One Side

Idlers

Transmitting Power through a 90 Degree Angle

Belt Splicing

Power Transmission Rules

Elevator Belts used for Power Transmission

Ancillary use of Belts

Chain Power Transmission

Chapter 7: Grist Chute Construction and Restoration

Chute Fabrication

Chutes and the Angle of Repose

Gates

Bagging Stations

Wickets

Chute Installation - Those Troublesome Angles

Chapter 8: Bucket Elevator Restoration

Slanting Leg Elevators

True Vertical Elevators

Elevator Boot and Leg Restoration

Elevator Buckets (cups) & Belting

Fabricating New Elevator Pulleys

Installing New Elevator Belts

Chapter 9: Steam Engine Restoration

Initial Condition and Restoration Goal

Preparation and Documentation

Disassembling the Engine

Replacing the Wooden Support Beams

Sandblasting and Painting

Repairing and Making New Parts

Alignment of the Engine during Assembly

Re-assembling the Steam Engine

Putting the Restored Steam Engine into Motion,

Feasibility Testing,

Design Decisions

Implementation

A Separate Motor for the Steam Engine

Chapter 10: Millstone Maintenance

Basic Steps

The Support Structure (hurst frame)

Leveling the Bedstone

Checking the Drive Shaft Tram

Millstone Dressing

Tools

First Steps

Painting the Millstone

Dressing the Stones

Balancing the Runner Stone

The Runner Stone Bail

The Grist Sweep

Flour Milling Issues

Chapter 11: Dating Methods

Gudgeons & Bearings

Dating Machinery with Nails

Threaded Fasteners

Mortise & Tenon Mounts

Dating by Research

Dating by Dendrochronology (Tree Ring Dating)

Bibliography & Index